Posts Tagged ‘experiment’

Vacuum Formed Project Enclosure

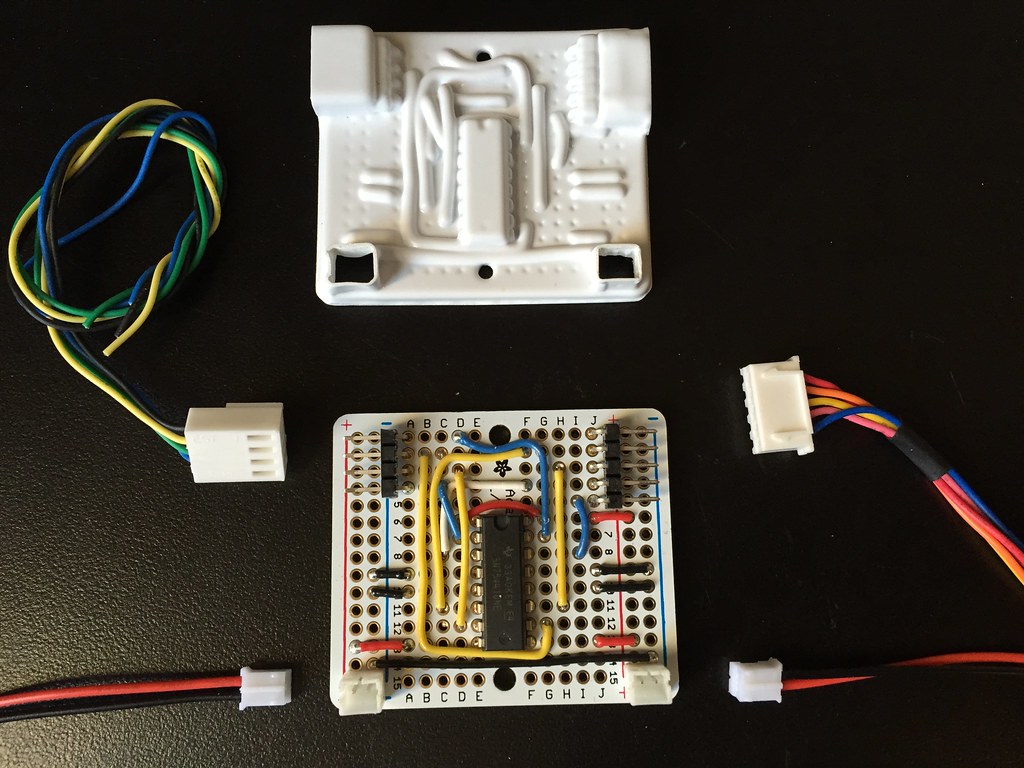

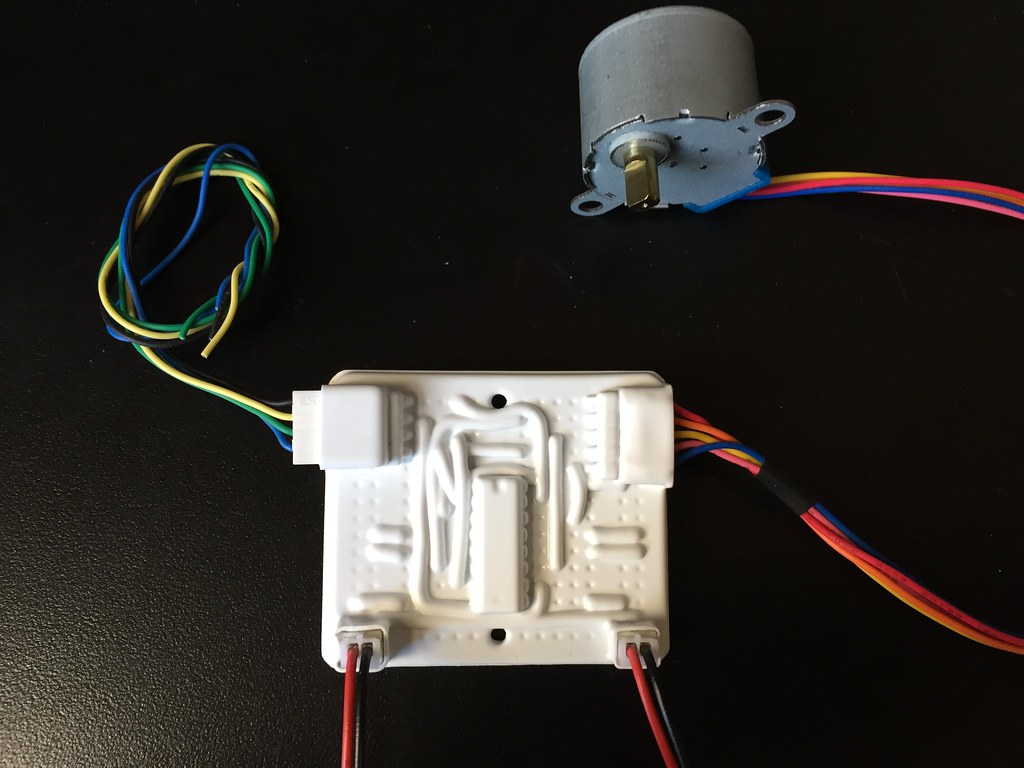

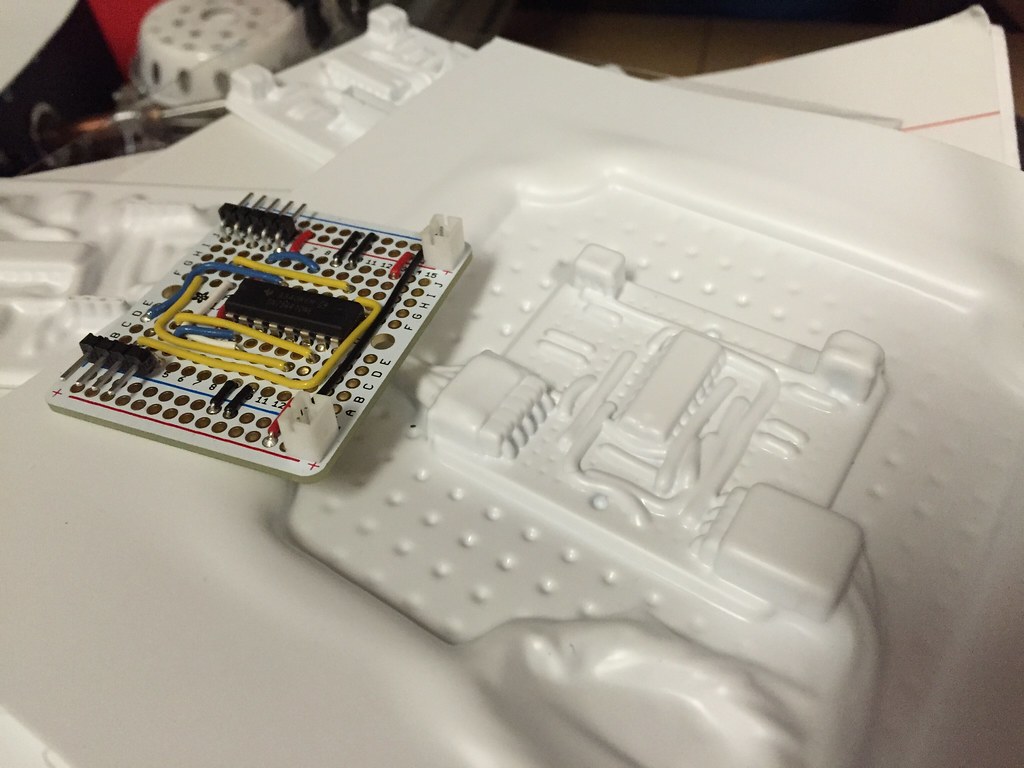

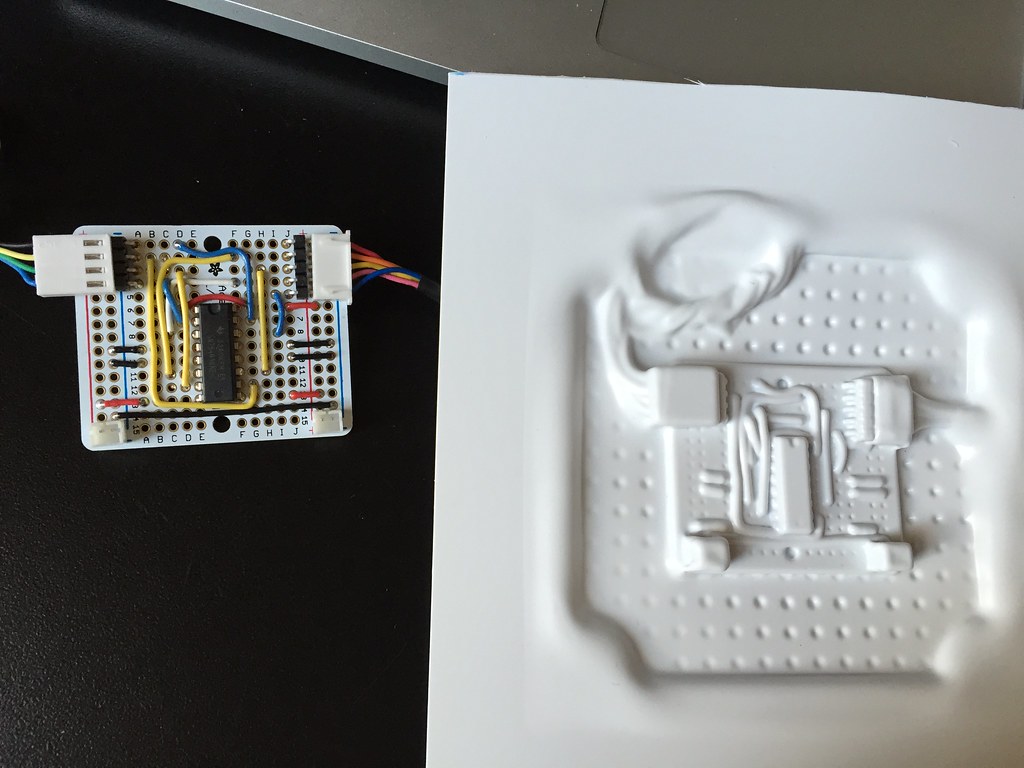

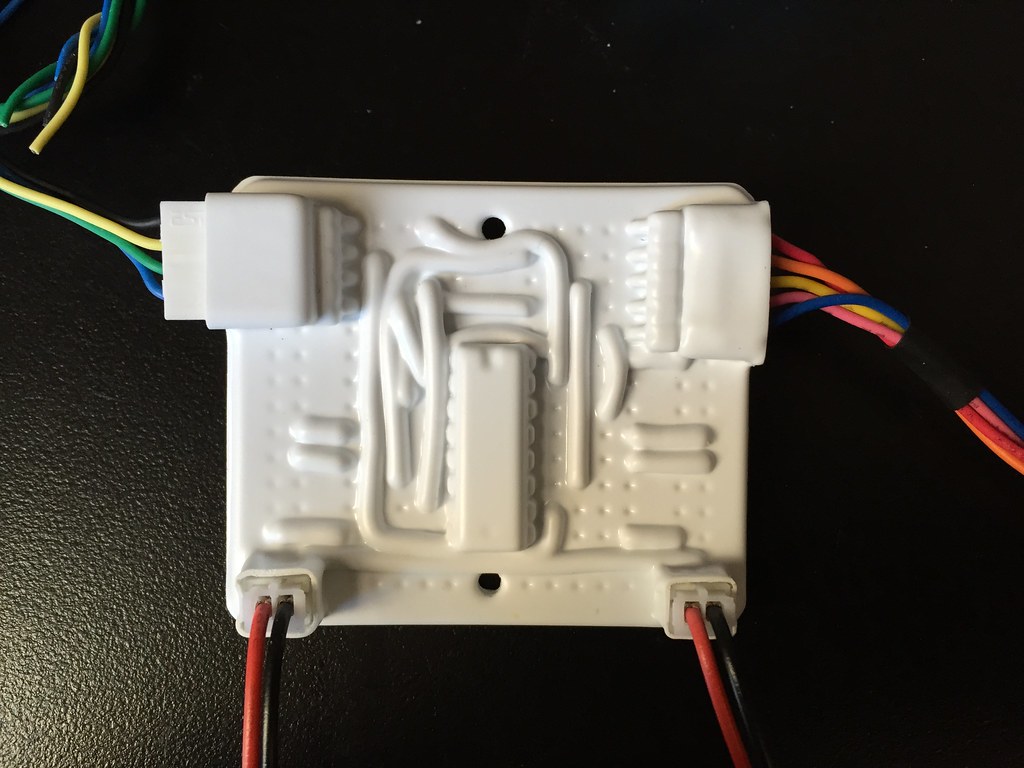

Monday, December 5th, 2016Finally, finished an idea I’ve had kicking around for a little while. I vacuum formed some styrene over a stepper motor circuit board, to be a quick custom project enclosure.

I formed it directly over the circuit board. After a little trimming and sanding, the cover fits great.

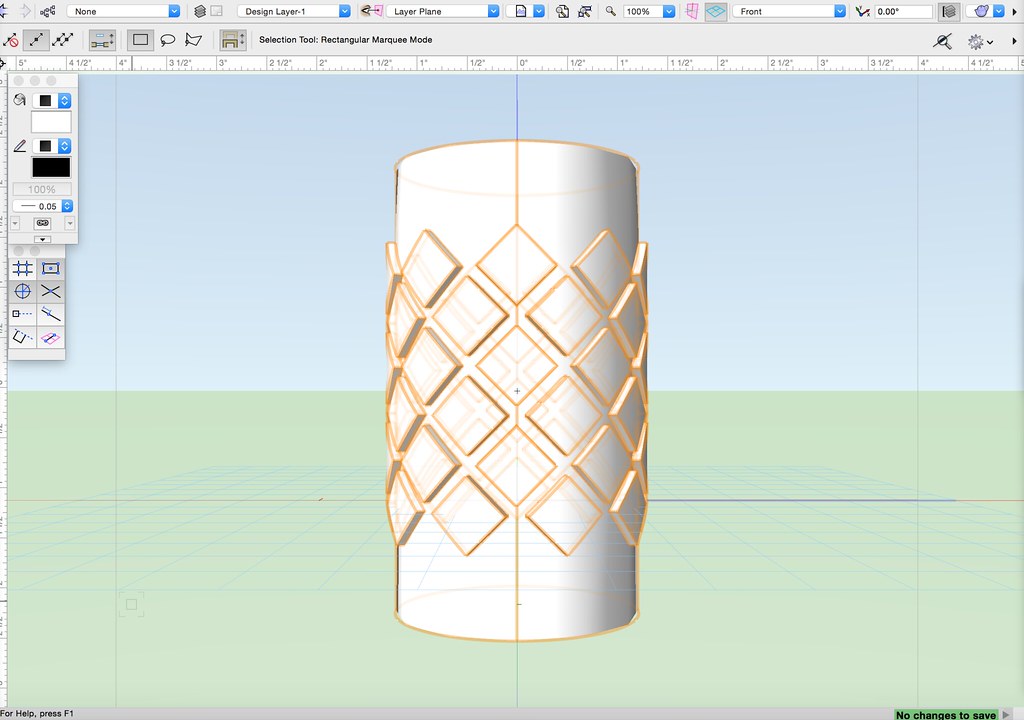

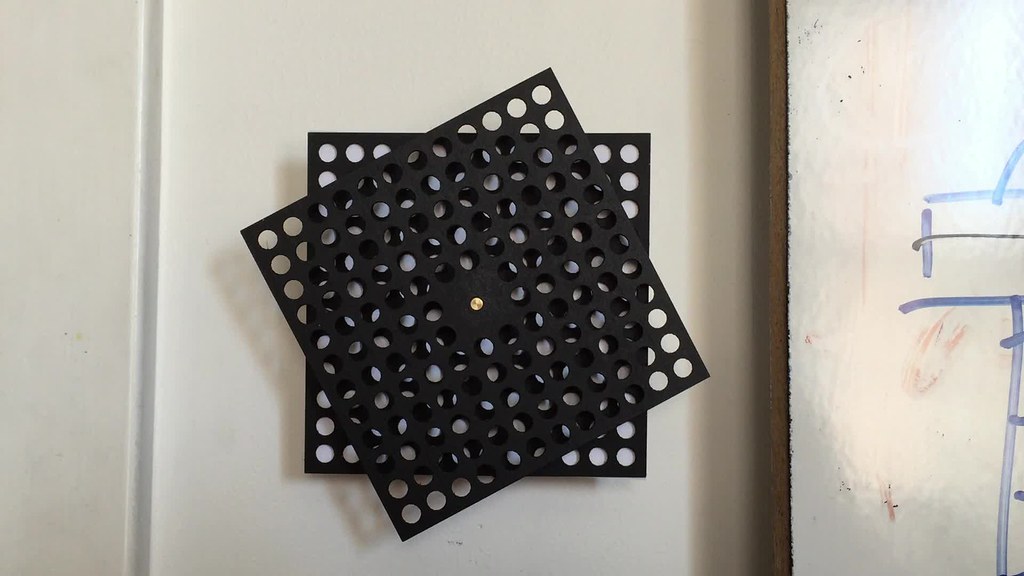

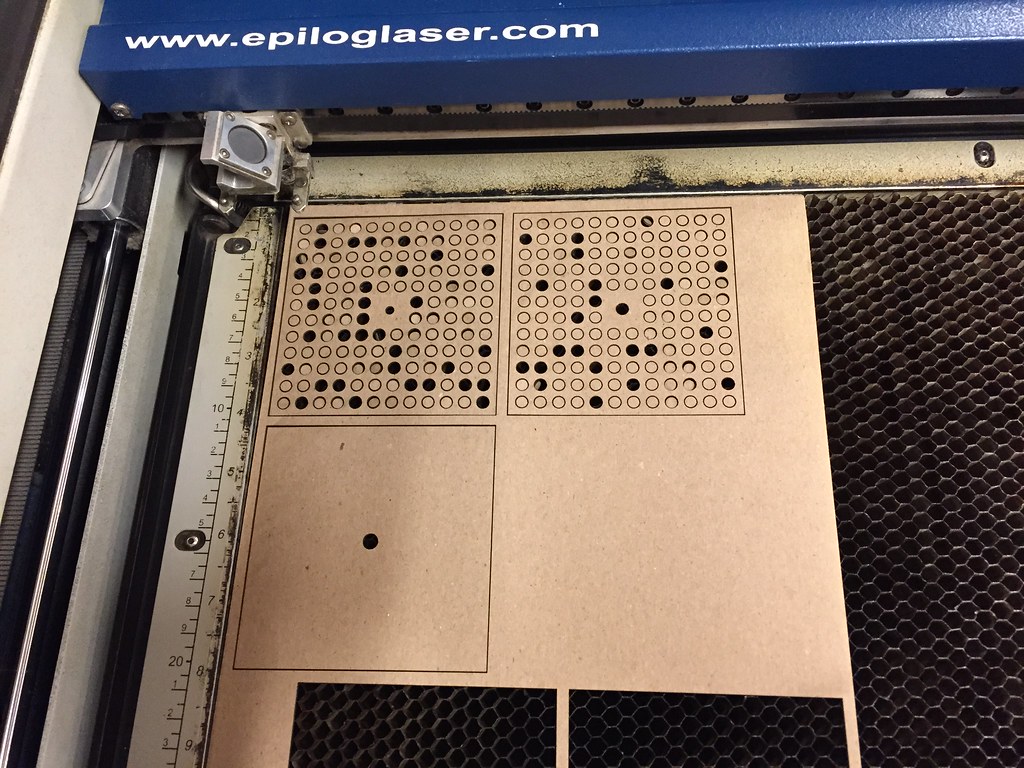

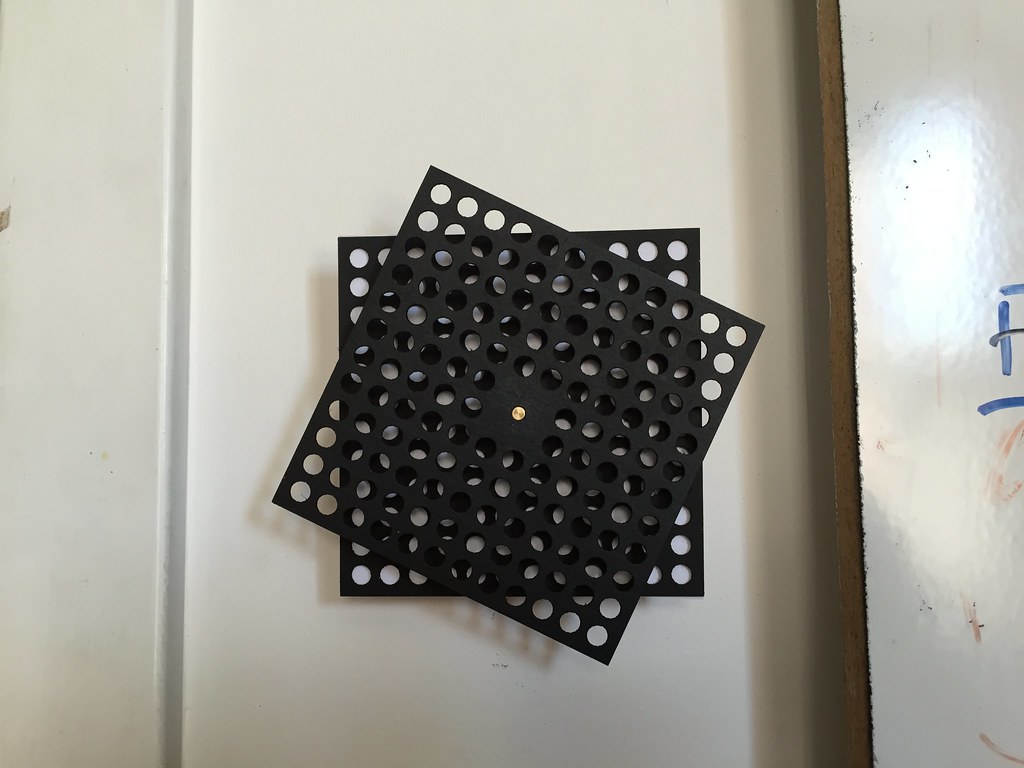

Moiré Pattern Clock

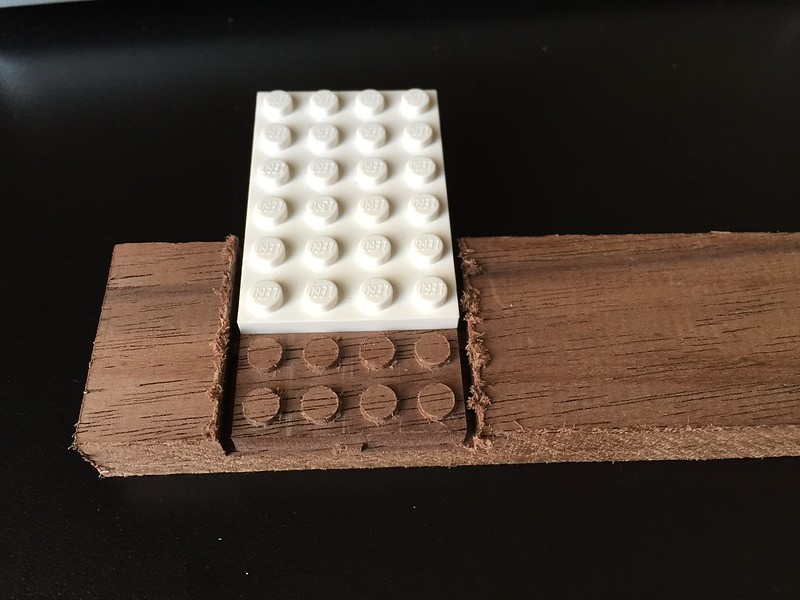

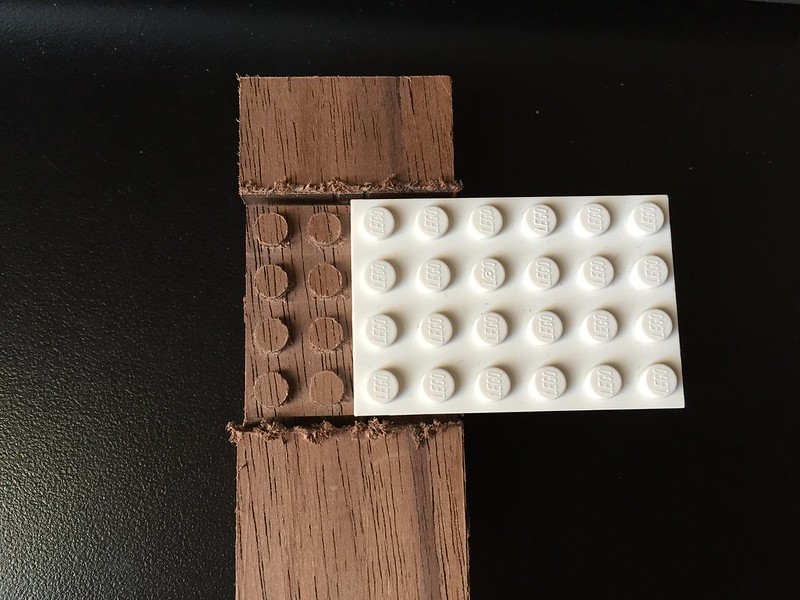

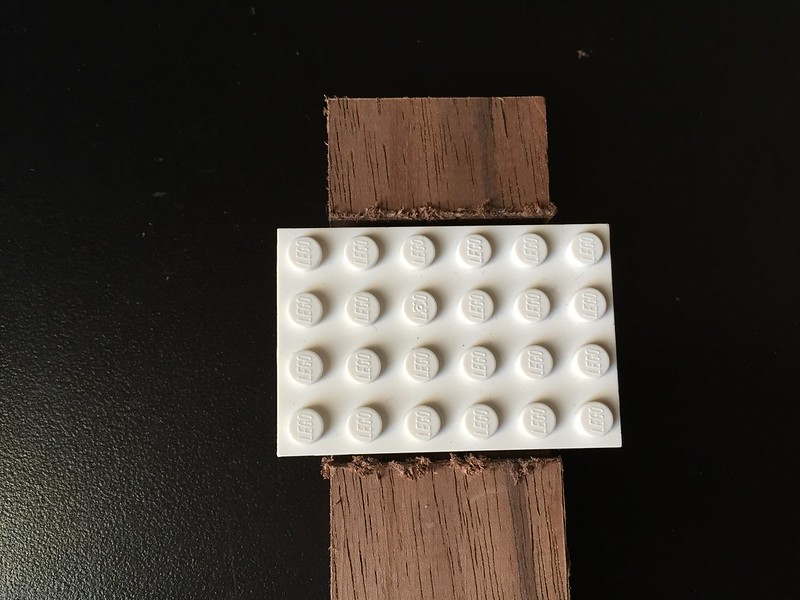

Tuesday, July 5th, 2016Wooden Lego Experiment

Tuesday, July 14th, 2015Milled a quick wooden Lego experiment. I can’t believe it fit the first try. Heavily influenced by Notcot.

More to come.

Experiment with Turned Aluminum and Powder Coating

Monday, April 27th, 2015Turned Plywood

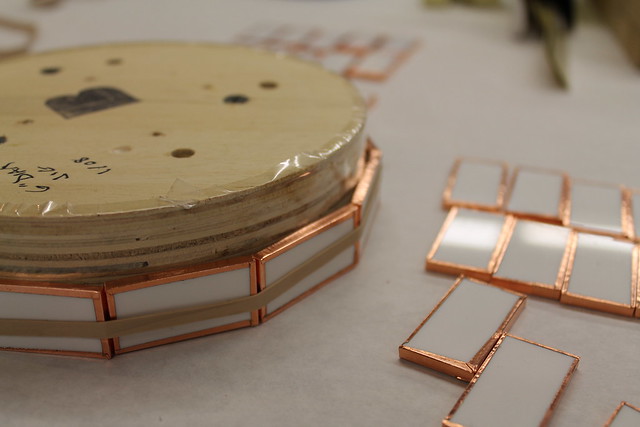

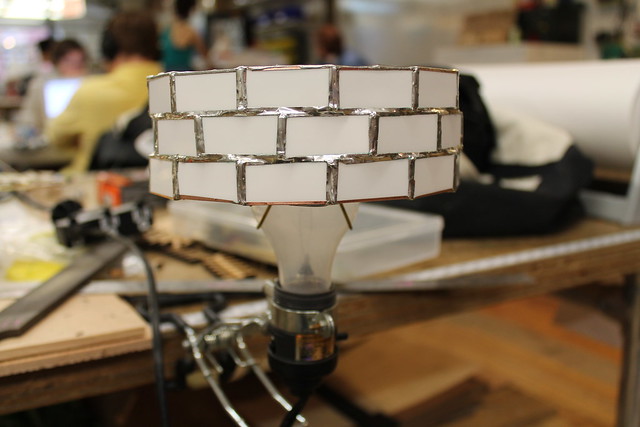

Sunday, March 15th, 2015Curving Metal

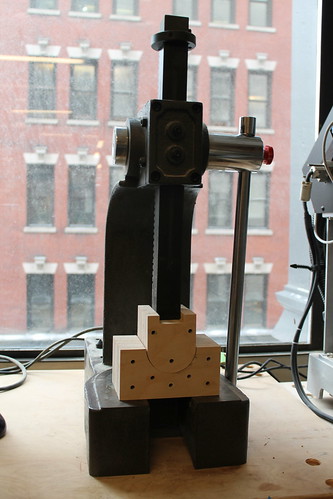

Tuesday, February 3rd, 2015I’ve been trying to curve small metal pieces without shelling out for a slip roll. CNC’d some male and female banks for the arbor press, and pressed some test pieces. The results were just meh.

There was some crimping that I’m not crazy about. Good in a pinch though. Maybe I’ll just break down a buy a roller.

Aluminum Space Helmet?

Thursday, December 4th, 2014This part started out as a quick demo on how to drill into a pipe (found on the ITP Fab site), but has morphed into something more. I’m thinking robot head (of course) or some sort of space/diving helmet.

I started with an off-cut piece of aluminum speed rail tubing (this stuff is everywhere around ITP), drilled a 1.5″ diam hole with a hole saw and jig, turned it on a metal lathe, and then made a retaining ring. I’m particularly proud of the ring: 4 evenly spaced holes, tapped for 6-32 threads, and secured by set screws.

These parts has no purpose other than getting my chops back and the pure joy of milling parts.